Specific research about the Hexachrome printing output- CMYKOG (Cyan, Magenta, Yellow, Black, Orange and Green), to establish and build my own knowledge for content for my ISSUU- based publication design for print manual- which can be seen developing on my Design Practice blog over the forthcoming days and weeks.

DEFINITION OF HEXACHROME

Web definitions

- Hexachrome was a six-color printing process designed by Pantone Inc. In addition to custom CMYK inks, Hexachrome added orange and green inks to expand the color gamut, for better color reproduction. It was therefore also known as a CMYKOG process.

- A version of hi-fi (high fidelity) printing involving six color separation.

- The set of six process colors (cyan, magenta, yellow, orange, green and black) designed to widen significantly the color combinations possible when compared to the combinations available with the standard four process colors (cyan, magenta, yellow, black).

- A proprietary color separation process, developed by Pantone, that uses six (6) instead of four process colors.

- Where two extra colours are added to CYMK to expand the gamut possible, green & Orange.

- The Hexachrome printing process uses a a colour model based on six primary colours as opposed to the traditional four colour process. As well as cyan, magenta, yellow and black, Hexachrome also adds orange and green into the range. ...

Hexachrome

Hexachrome was a six-color printing process designed by Pantone Inc. In addition to custom CMYK inks, Hexachrome added orange and green inks to expand the color gamut, for better color reproduction. It was therefore also known as a CMYKOG process.

Hexachrome was discontinued by Pantone in 2008 when Adobe Systems

stopped supporting their software. While the details of Hexachrome were

not secret, use of Hexachrome was limited by trademark and patent to those obtaining a license from Pantone.

Software

In order to use the Hexachrome process in a digital printing process, Pantone produced a plugin for Adobe Photoshop that allowed the designer to work in an RGB color space more typical of computer work. Using a six-channel ICC profile, this was then converted to the Hexachrome gamut as part of raster image processing.

The plugin was discontinued by Pantone in 2008 because Adobe Systems no longer supported Pantone's Rosetta (legacy) plug-in format.

All About Colour — A Guide to Commercial Colour Printing

How does commercial colour print work?

We use four main printing processes, depending

on the requirements of your job. This article gives you the basics of commercial

colour printing so you can appreciate why we suggest the processes we do

when quoting for your job.

Full colour process printing (also known as CMYK)

Process colour uses just four colours of ink

– cyan, magenta, yellow and black – to produce a very wide range

of colour possibilities, ideal for printing photographs. Because we specialise

in process colour printing, and we batch jobs together for economy, it can

often be cheaper to print even a simple two-colour design using process colour

rather than spot colour.

Spot colour printing

A spot colour is simply an exact colour of

ink, mixed to your precise requirements. Firms with a recognisable colour

brand (EasyJet orange; DynoRod fluorescent red) would always specify spot

colours to ensure consistency of their brand.

It often comes as a surprise to customers

to find spot colour printing is more expensive than full colour printing.

This is due to the labour involved with spot colour

printing – first the ink has to be mixed from 14 'ingredient' colours;

then the press is loaded with the ink; the job is printed; then the press

has to be washed down afterwards ready for the next spot colour job. This

labour requirement makes spot colour printing, especially in smaller quantities,

disproportionately expensive.

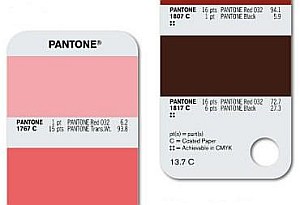

Spot

colours are most often specified in Europe and North America using the Pantone

system. Swatch books like the one shown here are used to select colours,

and the

'ingredients' for that colour of ink are shown underneath.

Spot

colours are most often specified in Europe and North America using the Pantone

system. Swatch books like the one shown here are used to select colours,

and the

'ingredients' for that colour of ink are shown underneath.

Where the four-dot symbol appears underneath

the colour (as in the example on the right here), the colour can be printed

almost exactly using the four-colour process described above, saving money.

Hexachrome printing

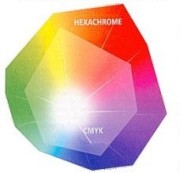

As

the name suggests, Hexachrome printing uses six colours of ink, rather than

the basic four colours used in process (CMYK) printing.

Hexachrome uses purer cyan, magenta, yellow and black inks, supplemented

with Pantone Hexachrome Orange and Pantone Hexachrome Green to

give a dramatically increased range of colours, as shown in the diagram

to the right.

As

the name suggests, Hexachrome printing uses six colours of ink, rather than

the basic four colours used in process (CMYK) printing.

Hexachrome uses purer cyan, magenta, yellow and black inks, supplemented

with Pantone Hexachrome Orange and Pantone Hexachrome Green to

give a dramatically increased range of colours, as shown in the diagram

to the right.

By using six colours instead of four, Hexachrome

can, in effect, reproduce a vast number of spot colours. Consider a range

of ten over-the-counter pharmaceutical products where each outer

package within

the brand is printed using two unique spot colours.

To print all these packages using standard spot colour (see above) would

require 20 plates to accommodate all the spot colours used, ten separate

press runs

and wash-ups,

and 20 spot colour inks.

Using Hexachrome, the ten packages are arranged

on one sheet and printed at the same time, thereby requiring only one

extended

press run, six plates and six Hexachrome inks, all without loss of colour

integrity. The resulting savings by printing in Hexachrome can be substantial.

MetalFX® printing

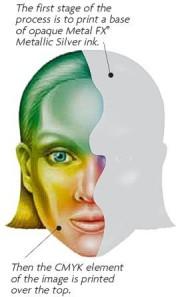

MetalFX® works

on the basis that CMYK (see above) inks are transparent – so when printed

on top of specially modified silver ink (MFX Base Silver), it will allow

the

silver

to show

through the CMYK, and thus create the illusion of unlimited metallic colours.

The MFX Base Silver has special qualities that allow

the CMYK inks to adhere to it.

MetalFX® works

on the basis that CMYK (see above) inks are transparent – so when printed

on top of specially modified silver ink (MFX Base Silver), it will allow

the

silver

to show

through the CMYK, and thus create the illusion of unlimited metallic colours.

The MFX Base Silver has special qualities that allow

the CMYK inks to adhere to it.

The MFX system enables you to create

eye catching designs by enabling you to integrate metallic colours into photographs

and create unlimited metallic colours on the same job, by only using one

extra colour. Ever wanted to have Gold, Silver and a Bronze on the same job,

but never had the budget to use more than one metallic colour? Well now with

MFX you can have all three – and 612 others as well – just by

using the MFX system

and its special silver ink.

If you would like to incorporate metallic colours

in to your next design simply design in CMYK as normal. Please supply us

with a printed proof, accompanying your file, detailing the areas to be metallised

and the colours

to be used.

Only licensed printers can print using MetalFX. Any printer

using the system without a licence would be breaking copywright, patent

and IP rights of MetalFX. A printer that has not run the MetalFX print

trials and been approved will not know the specification for the print

process and the job will not output correctly. Always use a licensed

printer if you are intending to use MetalFX in your next design.

IMAGES OF HEXACHROME

http://edliveshere.com/assets/issue05/5_chart_2.gif

No comments:

Post a Comment